Packaging

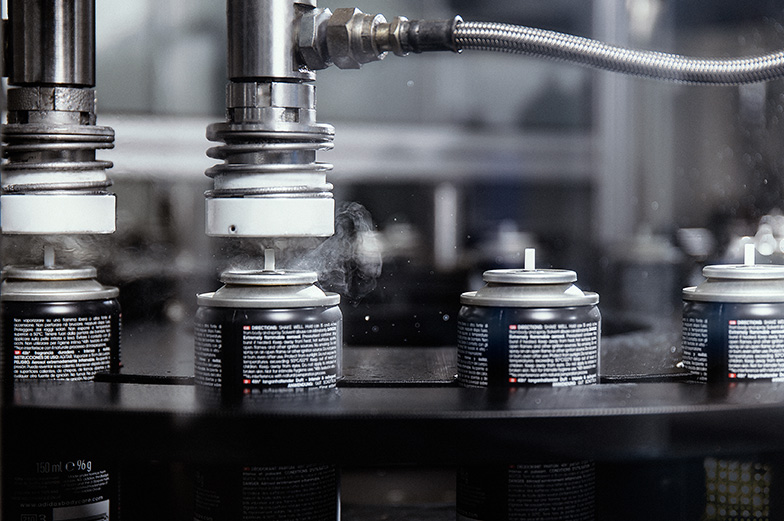

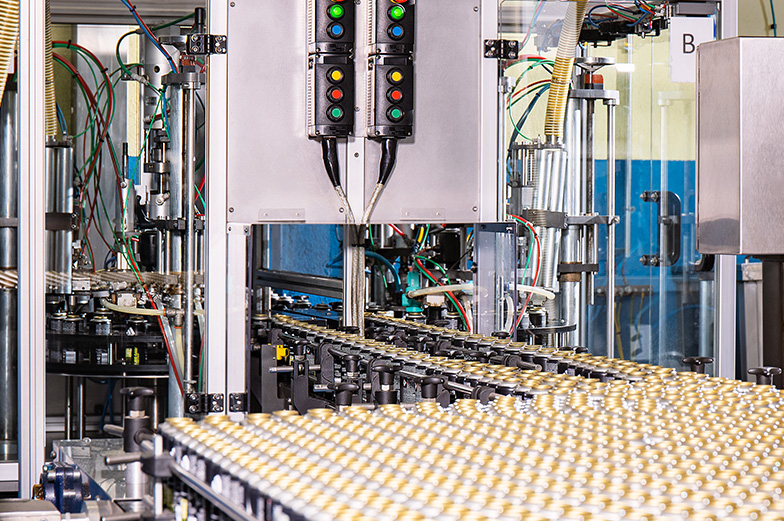

The packaging lines are equipped with different degrees of automation, allowing great flexibility and access to any type of series, covering all types of formats and products.

- Isobutane/Butane/Propane (GLP)

- DME

- Pure propane

- Pure isobutane

- R-134A – R-152A

- Compressed gases: N2 and CO2.

The packaging lines have a weighing and registration system for 100% of the units produced, as well as water baths at 50ºC.

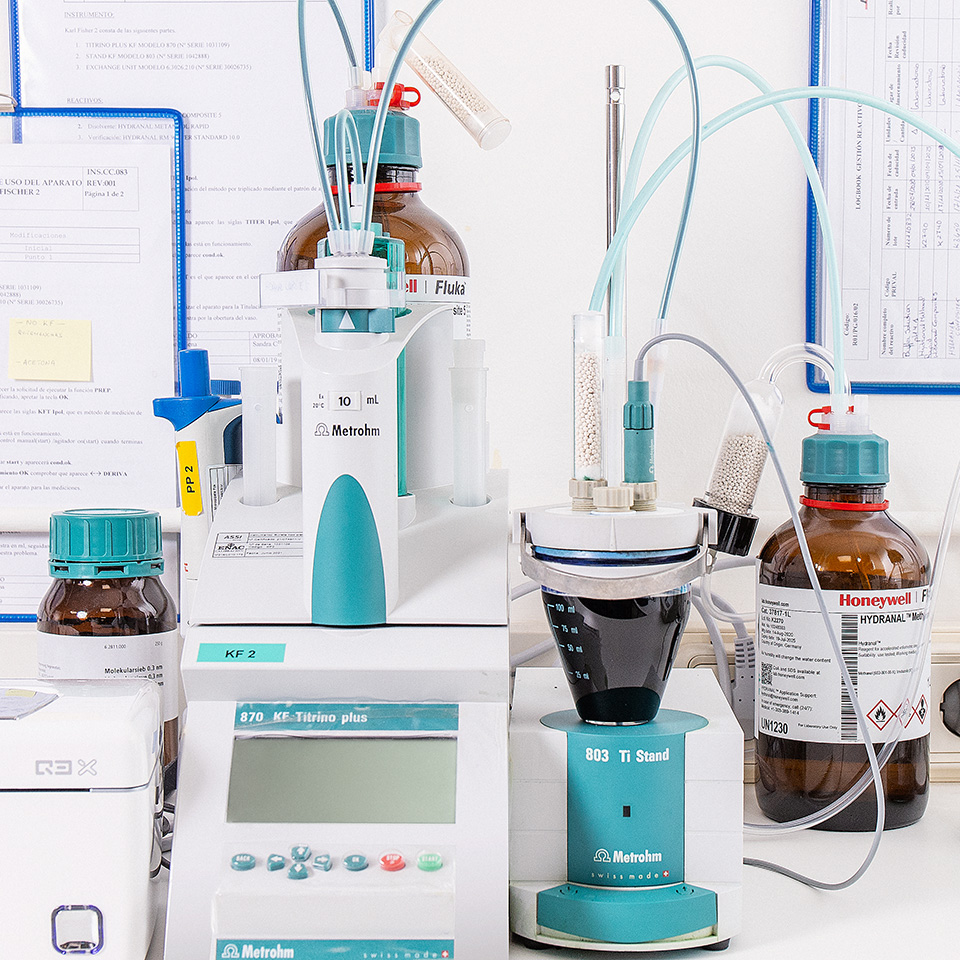

R+D+i Laboratory

Our facilities include a R+D+i Laboratory with all the necessary technology, and we have extensive experience in the sector.

We have a professionals team of chemical and pharmaceutical who are highly experienced in R+D+i.

We have a Research and Development Laboratory for aerosol products that comply with current European regulations. In this way, we offer our Customers complete solutions, both for manufacturing and packaging, that respond to their specific needs.

We work closely with them, ensuring strict confidentiality and exclusivity. We develop formulas that respond to market demand and that our Customers can personalise, adding different perfumes, active ingredients, etc.

For this, our R+D+i Laboratory includes the following equipment:

- Applications Laboratory

- Equipment for compatibility and stability tests (stoves, glass containers…)

- Dry residue stove

- Desiccator

- Digital hydrometer

- Karl Fischer Moisture Meter

- Refractometer

- Automatic acid-base titrator

- Gas chromatograph

- Ph-meter

- Fume cupboard

- Scales

- Glass cylinders

- Can seamer

Quality and safety

In our laboratories we carry out different types of physical-chemical controls on all products, as well as regulatory surveillance.

At PREVAL we receive the corresponding audits from the Competent Authorities, as well as from our main Customers, and we carry out continuous monitoring and updating of the regulations applicable to aerosols, to guarantee compliance with current European regulations both for cosmetic products and other aerosol products, as well as in terms of risk prevention and environmental protection.

Our 6 packaging lines give us a capacity to package over 50 million aerosols per year.

Manufacturing

Manufacturing The product is manufactured following the Customer’s specifications, complying at all times with the requirements, characteristics and demands set by the Customer We guarantee its quality carrying out the necessary physical-chemical controls.

We have three manufacturing rooms measuring 300 m2, one for cosmetic products and health products, another for veterinary pharmacological products and a third for the rest of the products, physically separated. In addition, all the manufacturing rooms have independent weighing areas, as well as reactors with capacities from 1,000 to 3,000 litres.

Purchasing, Logistics and Commercial

Full control of the supply chain

Purchasing

We manage both supplies and stocks for our Customers. We offer great response capacity, as well as great flexibility, keeping the Customer permanently informed of the situation of their products in our facilities.

Logistics

The distribution of our warehouses allows us to differentiate between the areas destined for raw materials, components for packaging as well as the finished product.

- 4 liquefied gas tanks (LPG, DME, Propane), with a total capacity of 128,000 l.

- 1 tank for Ethanol with a total capacity of 30,000 liters.

- Raw materials warehouse with capacity for 300 Euro pallets

- 2 component warehouses with a total capacity for 2,350 Euro pallets

Commercial

Our Commercial department offers a fully personalised and technical treatment, providing quick and effective responses to the needs of our Customers and ensuring their total satisfaction.